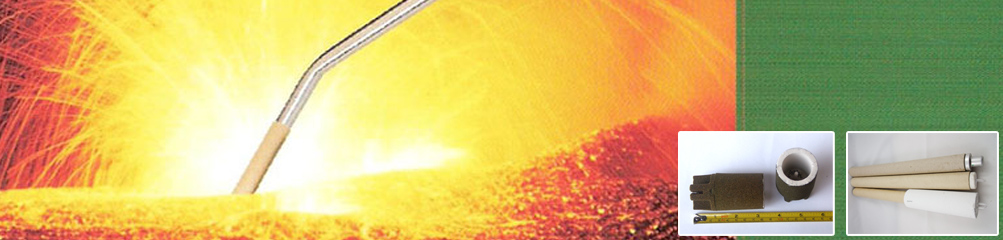

The thermal analysis of quality of molten iron take iron ladle into the sample cup in specific thermal conditions, the thermal analyzer first record within the next sample cup of hot metal solidification temperature curve.

Through the solidification temperature curve analysis to identify the hot metal solidification process of various phase transitions characteristic parameters. Characteristics of phase change parameter values into the mathematical model and the solidification microstructure, which can calculate the control parameters of the decision of molten iron solidified organization.

|

Name

|

Stove-Front Molten Iron Quality Management Meter |

Code

|

CE-2000

|

||||

|

FUNCTION

|

Mensurate

|

Quick measurement of CE, C%, Si%, TL, TE, Cooling Curve Iron Temp.(TP) and Spheroidization Rate (SG) within 3 minutes. And can predict extending strength. Great precision and excellent stability. |

|||||

|

Composition Calculation |

Automatically calculate composition according beforehand set composition and Iron quantity. |

||||||

|

Composition Adjustment |

Automatically calculate out the composition adjustment point according actual measurement. |

||||||

|

Storage Function |

Store tested information for checking anytime, transferable.

|

||||||

|

Browse Function

|

Browse history record like CE, C% and Si%, get trend chart.

|

||||||

|

Communication Function

|

Standard RS-232 Interface, memorize and display testing information when connected company and LED. |

||||||

|

Print Function

|

Can print iron brand name, testing date, time, cooling curve, CE, C%, S%, TP, SG, Extending Strength. |

||||||

|

Enactment Function

|

Faceplate button, Simple and convenient operation. In order to adapt different iron liquid, it can setup 8 testing line, 8 composition and 8 kind of iron molten point. |

||||||

|

SPECIFICATION

|

CPU

|

Special designed computer |

Work Tem. |

0-40 ℃

|

|||

|

Display

|

15 inch LED |

Work Humidity |

20%--70%

|

||||

|

Memorize Equipment |

3.5 inch HDD |

Connect Storage |

FDD floppy disk drive |

||||

|

Power

|

AC 189-260V, 47-63Hz |

Power Consume |

250W

|

||||

|

Input

|

Keyboard and LED light swift |

Print Output |

Standard Parallel |

||||

|

MEASURE SPE.

|

Measure Item |

Measure Range

|

Measure Precision |

||||

|

Thermocouple Type |

JIS-K Sensor (CS/SG) |

JIS-R Sensor (TP) |

|

||||

|

Test Tem. |

2000-2400 ℉

|

0---1760 ℃

|

+/- 0.1% +/- 2 ℉ |

||||

|

CE

|

3.20% - 4.83% |

|

+/- 0.10% |

||||

|

C%

|

2.80% - 4.20% |

|

+/- 0.05% |

||||

|

Si%

|

0.90% - 3.00% |

|

+/- 0.10% |

||||

|

Sensitive Rate |

1 ℉

|

1 ℃

|

|

||||

|

Sampling Rate |

0.5 Second |

0.5 Second |

|

||||